Case Studies

Case Studies

- Construction of A New Organic-inorganic Composite Emulsion and Its Enhanced Mechanical Properties of Oil Well Cement(Part 1)

- Construction of A New Organic-inorganic Composite Emulsion and Its Enhanced Mechanical Properties of Oil Well Cement(Part 2)

- The Application Prospects of DeepSeek Large Model in Petroleum Engineering(Part 1)

- The Application Prospects of DeepSeek Large Model in Petroleum Engineering(Part 2)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 1)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 2)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 3)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 1)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 2)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 3)

A microchannel model was established based on the pore size distribution characteristics of natural rock cores in Daqing Oilfield. The deformation and flow characteristics of dispersed and continuous phases in heterogeneous systems were considered. A flow model was established using phase field method and solved using finite element method. The generation of dispersed phase particles in microchannels was simulated, and particle sorting was achieved. The influence of matching coefficient and pore throat ratio on particle sealing performance in micro pore throat structure was studied. The results indicate that when particles undergo elastic sealing in the micro pore throat structure, the pressure at the entrance of the pore throat exhibits periodic changes as the particles migrate through it; The optimal matching coefficient between particles and pore throats is [1.0, 1.4]. Within this range, particles can temporarily seal at the entrance of the pore throats, and after deformation and migration through the pore throats, they return to their original shape; When the pore diameter is the same, the larger the matching coefficient and pore throat ratio, the greater the particle passing pressure; The larger the particle size, the smaller the critical pressure value for particles to pass through.

With the continuous expansion of the field and scale of oil exploration and development, how to further improve oil recovery rate has become an urgent problem to be solved. In recent years, research has found that heterogeneous systems formed by the combination of homogeneous systems and particles have good displacement effects, especially the particles have deformation ability, which can achieve alternating sealing and dynamic profile control, which is of great significance for improving the sweep coefficient. At present, research on the performance and oil displacement effect of heterogeneous systems mainly includes indoor core displacement experiments, microscopic visualization experiments, numerical simulation of oil displacement, and theoretical derivation. Through physical simulation experiments, the permeation adsorption characteristics and sealing performance of particles under multiple factors were evaluated. A mathematical model was established for particles and their transport process in porous media through numerical simulation and theoretical derivation. The tracking of particle transport paths was achieved, and the effects of particle viscoelasticity and residual resistance coefficient on their flow behavior were studied.

To characterize the particle sealing performance, researchers introduced matching coefficients to evaluate the adaptability between particles and pore throats. By synthesizing particles through experiments and studying their particle size, swelling and injection properties, the sealing performance of particles on pore throats was evaluated. The researchers also established corresponding models for calculating particle diameter and mechanical properties, characterizing the critical particle size after particle expansion, and providing a particle size range that matches the high water content reservoir conditions in the later stage. The analysis of the injection pressure curve and the characteristic parameters of displacement control shows that particles within the optimal matching coefficient range have the best sealing performance.

The above research on the rheological properties and particle sealing performance of heterogeneous systems shows that the best sealing performance can be achieved when the matching coefficient is good. However, quantitative characterization of the factors affecting particle sealing performance has not been conducted from a microscopic simulation perspective, and the influence of pore throat ratio on particle sealing performance has not been studied. Therefore, based on the pore size distribution characteristics of natural rock cores in Daqing Oilfield, a type of microchannel with particle generation effect is designed to achieve particle generation and sorting. Study the pressure variation characteristics at the entrance of the pore throat during the process of elastic sealing; Study the matching coefficients under different pore throat sizes and particle sizes, and divide the optimal matching coefficient range; Taking the pressure corresponding to a matching coefficient of 1.0 as the critical pressure for particle plugging, this pressure value is used as a reference to obtain the distribution range of pore throat ratio corresponding to effective plugging of particles with different particle sizes.

1.Formation of Heterogeneous Systems

Referring to the pore size distribution characteristics of natural cores in Daqing Oilfield and the particle size distribution characteristics of particle profile control agents after swelling in heterogeneous composite oil displacement systems, a flow model of heterogeneous systems was constructed using the phase field method, and finite element analysis was performed to achieve the generation and sorting of three types of particles with different particle sizes.

1.1Microchannel Model

Taking the natural core pore size distribution of Daqing Oilfield as a reference, the pore diameter was calculated to be between 12-300 μm and the throat diameter to be between 10-80 μm. Referring to the pore throat size distribution in this interval, microchannels at the micrometer scale were designed. Zhang Jingzhi et al. designed a T-shaped channel and simulated the particle generation process using the shear effect of liquid flow. However, the particles generated within the T-shaped channel will adhere to the channel wall in a disorderly form, and their shape is not an ideal circular shape, so they will not be considered. According to Newton's third law, if an additional channel is added on the opposite side of the vertical section of the T-shaped channel to establish a microchannel model, a pair of equal and opposite forces can be formed, which can stabilize the generation of particles without sticking to the channel wall. Therefore, microchannels are established to simulate the process of particle formation. The structure and mesh generation of the microchannel model are shown in Figure 1. In the microchannel model, the upper and lower channels are symmetrically distributed, and the horizontal section is the main channel formed by the heterogeneous system. The outlet end of the heterogeneous system can be connected to a pore throat structure model for studying the flow characteristics of heterogeneous systems.

.png)

1.2 Flow Model for Heterogeneous Systems

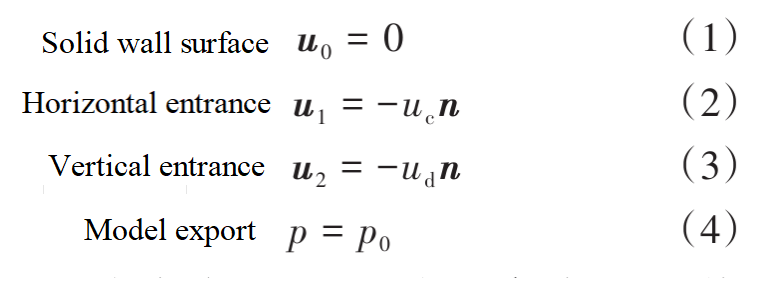

Establish a two-phase flow mathematical model in a two-dimensional microchannel model using the phase field method and solve it using the finite element method. In order to accurately describe the two-phase flow behavior and ensure mass conservation, the Naiver Stokes equation without slip boundary conditions is used to describe the fluid flow behavior, and the Cahn Hilliard equation is used to describe the phase separation process. The two equations are coupled using interfacial tension. Define the boundary conditions of the microchannel model, which means that the wall is a non slip boundary with neutral wetting, and the remaining boundary conditions are as follows:

The initial interfacial tension is 3 mN/m, the wetting angle is π/2, the viscosity of homogeneous system is 70 mPa∙s, and the viscosity of gel system is 1400 mPa∙s. The established two-phase fluid flow model is solved. Based on the microchannel model, the formation process of heterogeneous system in the microchannel was simulated by injecting the gel system as a dispersed phase at the rate of u1, and the homogeneous system as a continuous phase at the rate of u2.

At the initial moment, the microchannel is filled with a homogeneous system (Figure 2a). The particle formation process is as follows: ①.Before the gel system flows from the inlet end to the cross at the speed of uc, the homogeneous system flows from the two inlet ends to the cross at the speed of ud in the vertical direction, applying a pair of forces of equal size and opposite direction to the gel system, and the gel system is deformed under the effect of this pair of shear forces (Fig. 2b). ②.In the process of continuous forward migration, the front end of the gel system is split and continues to move forward by the vertical shear force and its own inertial force (Fig. 2c). ③.The particles inside the microchannel split and migrate forward with the homogeneous system (Figure 2d). From Figure 2d, it can be seen that the simulated particles and homogeneous system together constitute a heterogeneous system.

.png)

1.3 Particle Sorting

The distribution range of pore throats in natural rock cores was studied using CT scanning technology, and the pore throat size distribution of rock samples with different permeability was obtained. In heterogeneous systems, particles exhibit swelling characteristics. The particle size distribution after swelling in field experiments is statistically analyzed and used as a reference interval. When simulating the generation process of heterogeneous systems in microchannels, in order to ensure good matching between the simulated particles and pore throats, particle sorting is achieved by changing the initial conditions. According to the particle size distribution after swelling (Figure 3), the median particle size after swelling is 45μm, and the particle size distribution is concentrated in the range of 30-65μm. The particle size within this range is used as a reference value for particle simulation. After simulation, particles with particle sizes of 40, 45, and 60 μ m were selected for particle sealing performance research.

.png)