SOTU (Slop Oil Treatment Unit) Process

PRODUCTS & SERVICES

SOTU (Slop Oil Treatment Unit) Process

How SOTU Works

SOTU -- Slop Oil Treatment Unit

Mechanical strong gravity acceleration to remove the nucleation, solid - liquid separation demulsification.

First Stage mechanical separation gravity acceleration: 3500-4800g to realize solid-liquid separation.

Two-stage mechanical separation gravity acceleration: 6000-12000g, to achieve the separation of oil, water and solid.

Physical nucleation flocculation pretreatment process was used for extremely stubborn aging oil.

Aging Oil Production

Oil pollution caused by refinery process accidents, such as electric desalination accidents.

Original tank slop oil production.

Drilling cuttings, completion mud and perforation residue (new well)

Recovery of ground oil (onshore)

Failure to prevent sand underground

Waste oil of large power equipment in oil field (offshore oil platform)

Processing Power

Design capacity: 12 cubic meters/hour.

Actual average operating capacity: 120 -- 180 cubic meters per day (depending on oil and maintenance time)

Water-content in BS&W separated oil-phase at outlet: 0.3 -- -2.0% (distillation)

Water phase outlet OIW (oil in water) : 20-500ppm, after water treatment workshop can meet the discharge standard.

Installation and Operation conditions of SOTU

Dimensions: 6M(18 ') standard container.

Power: 3X380Vac, 50Hz, 95kw.2 x220 Vac 10 kw

Pipeline interface: adjustable on site.Compressed air 60-75 psi (drive pneumatic pump), fresh water 0.3-0.5 Mp, 3 M3/ day

Oil pretreatment temperature: 25-30℃above freezing point, the best temperature 92℃

Installation location: below Class I Division II

Waterproof and dustproof coefficient: IP 56

Technical features of SOTU

1. Physical pretreatment and nucleation

2. Strong gravity physics demulsifier and oil water separation

3. No chemical pollution of crude oil and reduces interference to refining process.

The benefit of the SOTU

1. Reduce the disposal amount of hazardous waste.

2. Oil recovery

3. Increase the crude oil storage capacity of the refinery, no slop tank is needed.

4. Avoid high-risk confined space operations

Installation and operation conditions of SOTU

SOTU Success Case 1 (As Shown Below)

SOTU was successfully developed in 2010.Firstly, it was put into field operation in cnooc's caofeidian oilfield (Anadarko). It runs continuously for 2 years and processes 30,000 parties.

.png)

SOTU Success Case 2 (As Shown Below)

In 2012, cnooc operated in Liuhua oilfield, Shenzhen branch.

Treatment of 12,000m3 sulfur-bearing dirty oil (additional preheating device)

.png)

SOTU Success Case 3 (As Shown Below)

In 2015, the Chengdao west project of Shengli oilfield of Sinopec successfully treated 2,000 cubic meters of drilling returned fluid

.png)

Site Analysis Report of Liuhua Oil Tanker Bilge Oil Processing

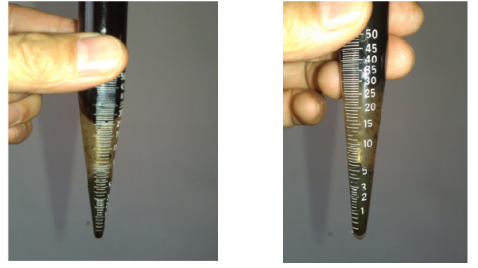

Oil Sample of first stage and second stage treatment

.png)

Field Analysis Report on the Disposal of Tanker Bilge Slop in Liuhua Oilfield

Before treatment, the upper slop tank slop oil was centrifuged and analyzed for water content is 30% and lower is 50%.

Solids are 10% by volume.It is the key to confirm the existence of oil-water emulsified solid suspension.

Field Analysis Report on the Disposal of Tanker Bilge Slop in Liuhua Oilfield

Section 1 Centrifugation after Treatment (Removal of Solid Suspensions)

Field analysis Report on the Disposal of Tanker Bilge Slop in Liuhua Oilfield

After the first treatment, the slag and oil were sampled separately, and the organic solvent was washed at room temperature, and the following data was obtained after filtration.

|

sample |

Weight(g) |

Filter paper weight(g) |

Weight after filter(g) |

Impurities (may contain wax, asphalt) |

|

|

g |

% |

||||

|

First level outlet oil |

6.53 |

0.0780 |

0.1106 |

0.0326 |

0.5 |

|

First level outlet oil |

0.59 |

0.0784 |

0.2507 |

0.1723 |

29.2 |

|

First level outlet oil |

2.83 |

0.0786 |

0.0959 |

0.0173 |

0.6 |

|

First level outlet oil |

0.48 |

0.0778 |

0.2143 |

0.1365 |

28.4 |

The content of solid impurities in the oil - water mixture after primary treatment does not exceed 0.6%.

The organic content of solid impurities after primary treatment depends on the characteristics and source of the slop oil.

Field Analysis Report on the Disposal of Tanker Bilge Slop in Liuhua Oilfield

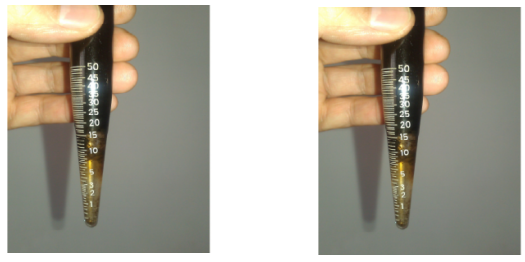

Centrifugal Results of Oil Samples after Secondary treatment

After secondary treatment, the water content in oil phase centrifuge analysis is 0.

Analysis of oil samples after two stage treatment

|

Sample |

Weight(g) |

Distilled water (g) |

Water content |

|

second level outlet Oil |

123.9 |

0.35 |

0.28% |

|

second level outlet Oil |

185.6 |

0.48 |

0.26% |

|

second level outlet Oil |

165.4 |

0.43 |

0.26% |

The oil after secondary separation meets the requirement of crude oil in refining process

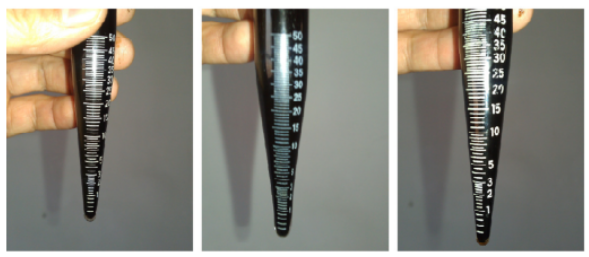

The Latest Successful Test Case-Cangzhou Refinery Waste Oil Treatment Test

Crude oil SOTU has been upgraded and transformed to improve its nuclear enhancement function.

The refinery has carried out the experiment of waste oil treatment, and the result of the experiment is better than that of the oilfield.

(There is still room for optimization of operation parameters). The experimental results are as follows:

|

Analyze project |

Dirty Oil Raw Materials |

Sample 1 |

Sample 2 |

Sample 3 |

Sample 4 |

|

Operating temperature |

45 |

55 |

70 |

60 |

60 |

|

Primary processing flow (m3 / h) |

|

8 |

6 |

8 |

8 |

|

Secondary processing flow (m3 / h) |

|

6 |

6 |

7 |

7 |

|

Product water content (%) |

50 |

0.7 |

0.4 |

0.5 |

0.5 |

|

Solid impurity content (%) |

3.2 |

1.6 |

1.2 |

2.8 |

2.8 |

|

Cut water oil content in water (mg/L) |

|

52.4 |

52.6 |

47.4 |

51.7 |

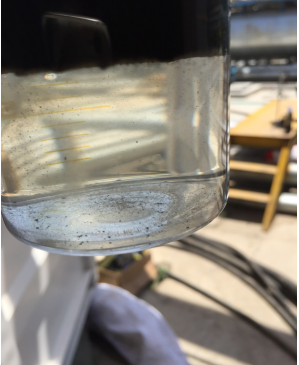

Oil and Water sample after two stage treatment

Water sample after two stage treatment

Floating on the surface is coke powder.

.png)

Separated oil

Limitations of SOTU

1. Sludge separated from SOTU process needs to be treated separately as a danger.

2. Physical labor intensity is relatively high. Operators need to carry solid waste manually (refineries can mix asphalt raw materials into the process)

3. Limitation of extreme cold climate conditions